Understanding 1PL to 5PL: Which Logistics Model is Right for Your Business?

- Yvonne Badulescu

- Jan 19

- 4 min read

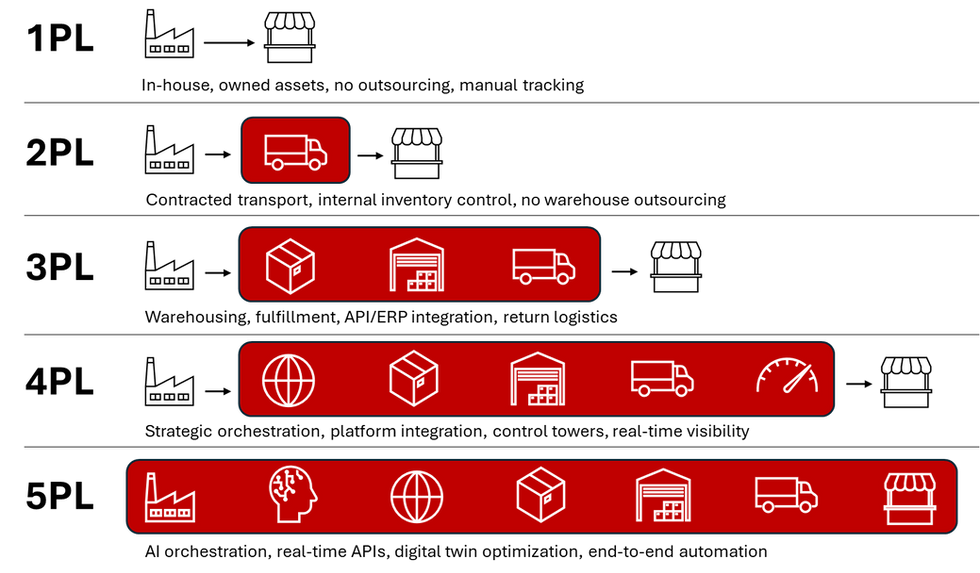

In today’s global and increasingly complex supply chains, understanding the right level of logistics outsourcing isn’t just helpful, it’s strategic. From self-managed operations to AI-driven orchestration powered by machine learning (ML), predictive analytics, and even generative AI for simulation and planning, logistics models today span from 1PL (First-Party Logistics) to 5PL (Fifth-Party Logistics).

This article breaks down each level in technical detail, highlighting what differentiates them, what makes them suitable for certain business contexts, and real-world examples, including companies operating in Switzerland and Europe.

1PL – First-Party Logistics: Total Internal Control

Definition: In a 1PL model, the company handles all logistics activities in-house. This includes storage, inventory handling, packaging, and transportation. It owns or leases its own assets (vehicles, warehouses) and does not outsource core logistics functions.

Best for:

Local or regional distribution

Perishable or handcrafted products

Businesses with limited logistics complexity

Desire for full control over timing, handling, and service quality

Key Characteristics:

Fixed cost-heavy (assets, labor)

Full control, low flexibility

Manual or semi-digital routing and tracking

No integration with external providers

Example: Chocolaterie Walder (Neuchâtel, Switzerland). An artisan chocolatier managing in-house cold-chain delivery to local customers.

Why not 2PL or 3PL? The additional cost and complexity of outsourcing are not justified for small-scale or local flows. Maintaining direct control is vital for freshness, service quality, and brand experience.

2PL – Second-Party Logistics: Transport-Only Outsourcing

Definition: In a 2PL model, the company outsources transportation or another singular logistics function (like warehousing), but still coordinates operations internally. A 2PL provider owns transport assets and executes physical movement.

Best for:

B2B businesses with simple distribution networks

Low to moderate shipment frequency

Internal inventory management but outsourced freight

Key Characteristics:

Contracted transport services

No system integration beyond tracking numbers

No inventory or multi-node coordination

Examples: ReCircle (Bern, Switzerland). Distributes reusable containers to foodservice providers using local courier networks.

Why not 1PL or 3PL? Owning logistics assets (1PL) increases overhead. 3PL would be excessive given the lack of need for warehousing or inventory services.

3PL – Third-Party Logistics: Outsourcing Execution

Definition: A 3PL handles multiple logistics functions, such as warehousing, order fulfillment, customs clearance, and transportation. Companies integrate their ERP or OMS with the 3PL’s warehouse or transport management system.

Best for:

E-commerce brands and SMEs scaling rapidly

Multi-SKU inventory needing stock rotation

Omnichannel fulfillment and returns

Key Characteristics:

WMS (Warehouse Management System) integration

APIs between ERP/OMS and logistics provider

Ability to scale seasonally

Return logistics supported

Some 3PLs now integrate machine learning to optimize pick-paths in warehouses, demand-based staffing, or delivery time windows based on historical data.

Example: Soeder (Zurich, Switzerland). Sustainable cosmetics company using a 3PL for inventory handling, pick-and-pack, and reverse logistics.

Why not 2PL or 4PL? 2PL can’t manage dynamic inventory or returns. 4PL would be overkill unless coordinating multiple 3PLs or regions.

4PL – Fourth-Party Logistics: Strategic Orchestration

Definition: A 4PL provides supply chain orchestration, managing multiple 3PLs, integrating data across systems, and acting as a single point of strategic control. They don’t execute logistics but oversee them.

Best for:

Multinationals managing regional 3PLs

Manufacturers with global supply and demand flows

Companies requiring real-time visibility and SLA management

Key Characteristics:

Control towers or supply chain visibility platforms

Logistics service procurement and management

Exception management and optimization

Cross-border or multimodal coordination

May leverage AI for exception prediction, lead-time variability modeling, or dynamic vendor performance monitoring.

Example: Logitech (Lausanne, Switzerland). Uses 4PL control towers to manage fulfillment from Asia to EMEA and Americas.

Why not 3PL or 5PL? 3PLs lack cross-provider coordination. 5PL would require predictive analytics and full supply chain digitization, which may not yet be in place.

5PL – Fifth-Party Logistics: Digital Ecosystem Orchestration

Definition: 5PLs go beyond service coordination, they digitally orchestrate entire supply chain networks. Using AI, APIs, and real-time data, they optimize inventory flows across geographies, channels, and partners.

Best for:

High-SKU, omnichannel businesses

Companies with advanced demand planning and fulfillment automation

Integrated planning-execution organizations

Key Characteristics:

AI/ML-driven routing, inventory positioning, and even generative AI for scenario planning, language-based demand simulation, or digital twin optimization

Tightly coupled with ERP, WMS, and TMS

Use of control towers, digital twins, and predictive analytics

Often involves real-time API calls for carrier selection and ETA optimization

Examples:

Procter & Gamble (EU): Uses Kinaxis for global control towers, integrating planning, inventory, and fulfillment execution in real time.

Nestlé Purina EU: Combines SAP IBP with fulfillment systems to optimize flows from production to pet retailers and D2C.

Why not 4PL? 4PLs can’t execute predictive, real-time decisions or integrate demand sensing into routing decisions. 5PLs automate what 4PLs coordinate manually.

Which logistics model is best for your business?

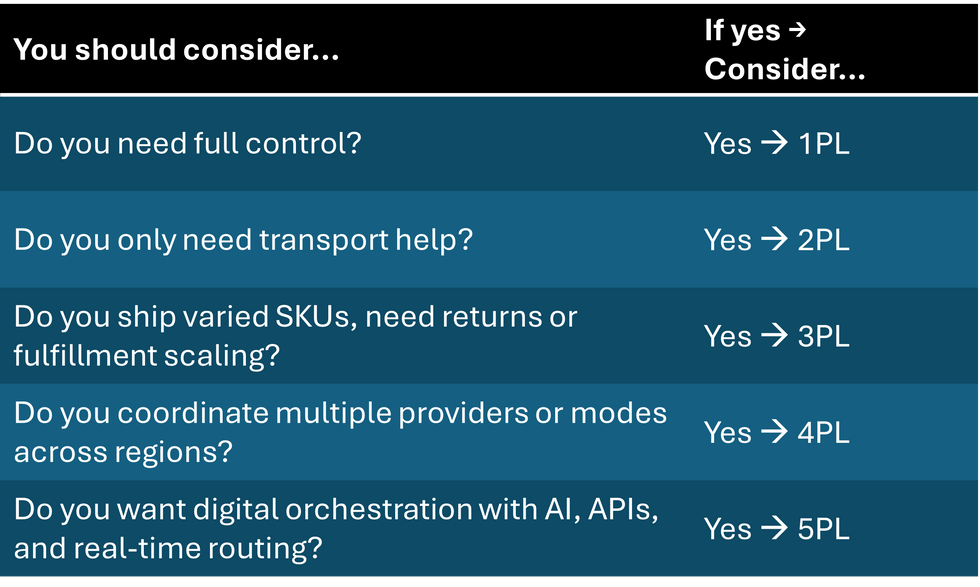

When selecting the most appropriate logistics model, consider the following decision points:

If your company needs full control over logistics operations, from warehousing to transport, and prefers not to outsource, then a 1PL model is the most appropriate. This setup is ideal for businesses that prioritize direct oversight and have the capacity to manage logistics internally.

If your primary challenge is transportation and you require help only with moving goods, but prefer to handle warehousing and inventory management yourself, a 2PL provider would be a suitable choice. This model supports businesses that need freight services without the complexity of multi-function outsourcing.

If your business involves shipping a variety of SKUs, handling returns, or requires scalable fulfillment due to fluctuating demand, then it’s time to consider a 3PL partner. 3PLs provide integrated services such as warehousing, inventory management, and e-commerce fulfillment.

For companies that coordinate multiple logistics providers or operate across regions and transport modes, a 4PL model is better suited. 4PLs act as strategic integrators, managing multiple 3PLs and offering end-to-end visibility, control, and optimization.

Finally, if your logistics needs involve digital orchestration, including the use of AI, APIs, real-time routing, predictive analytics, and tight integration between planning and execution systems, then a 5PL model is the most strategic option. This is typically used by advanced organizations managing complex, data-driven global supply networks. Companies exploring 5PL often invest in AI-driven systems not only to improve logistics but to transform decision-making, from predictive ETA adjustments to generative simulations of disruptions and recovery plans.

Logistics is no longer just an operational function, it's a strategic enabler. Whether you’re an artisan chocolate maker in Neuchâtel or a multinational shipping to 80 countries, choosing the right logistics model matters. The level of orchestration, control, scalability, and technology integration you need will define whether you stick with a 1PL setup or evolve into a digitally orchestrated 5PL ecosystem.

Comments